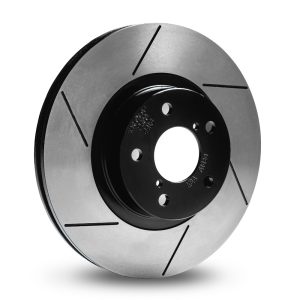

TAROX Performance Brake Rotors

In 1983 we manufactured the world’s first ever grooved brake rotor which has since been developed into the range of performance brake rotors that we offer today.

Every one of our rotors is manufactured from the highest quality casts or steel billets before being heat treated and balanced by hand for the smoothest possible surface.

- Every blank cast passes stringent quality controls

- Precision facing by CNC turning machines and TAROX built machinery

- Perfectly level surface machined to a tolerance approaching 0.015mm

- Ground individually by a specialised operator, resulting in that distinctive shine

- Structural stress relieving heat treatment at the end of each machining phase