- F2000 - long curved grooves

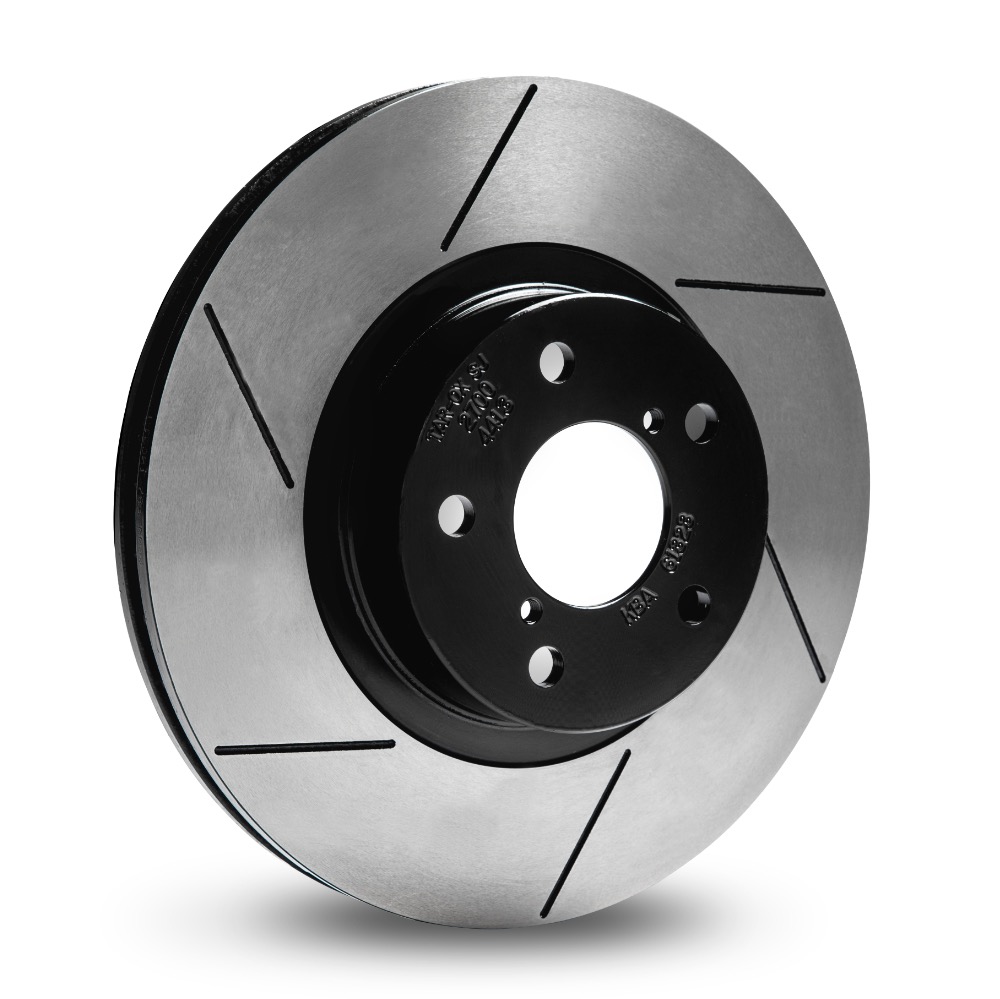

- G88 - 40 straight slots

- Sport Japan - drilled and slotted

- C83 - short straight slots

- D95 - drilled only

- ZERO - plain braking surface

Some options may not be available.

Please get in touch for more info.

$335.00

Some options may not be available.

Please get in touch for more info.

All TAROX performance brake rotors are based on original equipment specification, TUV approved castings, heat treated for strength and hand finished to ensure the smoothest possible braking surface. TAROX pads are their ideal partner for an optimised braking system.

For the full specification please see the 'ADDITIONAL INFORMATION'tab above.

First developed for use in touring cars over 20 years ago and often found in the TAROX range of big brake kits, the F2000 has forged a reputation as the toughest performance aftermarket brake rotor available. We have even observed a number of high end vehicle manufacturers using F2000 ‘style’ rotors on their range topping models.

The G88’s grooves feature an edge to edge design, ensuring absolute maximum dissipation of heat, while incorporating a chamfered leading edge, which ensures that the life of the brake pad is not decreased. The unique slots allow the G88 to run cooler than any other performance brake rotor tested against it. Available for rotors up to 330mm.

Sport Japan rotors are one of the only aftermarket performance discs to still feature fully drilled holes. To ensure ultimate performance and durability all Sport Japan rotors feature countersunk holes strategically placed so as not to affect the rotors structural integrity. An additional 6 slots on the braking surface act like a wiper, keeping the brake pad from glazing and removing excess dust while providing additional cooling.

The original groover. Created in March 1983 the C83 was the first grooved rotor ever offered for road going applications. Simple and still effective, the straight slots sweep the pad keeping the surface optimised for every application of the pedal. Ideal for applications where strength takes precedence over cooling and noise output is minimum. Excellent choice for road cars.

Although plain in appearance, the ZERO rotors are far from an original part. TAROX ZERO rotors are made from special high grade casts submitted to several levels of heat treatment. An outstanding resistance to high temperatures prevents warping and cracks. The final hand finishing leaves them incredibly smooth allowing them to mate to pads efficiently, increasing life of the rotor and pad. Perfect for both concourse vehicles and competition cars where regulations do not allow a modified brake setup.

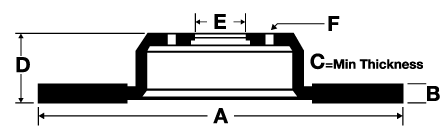

| Weight | 12.5 kg |

|---|---|

| TAROX Code | |

| Quantity | 2 Rotors |

| Axle | Front |

| Rotor Type | Vented |

| Vehicle Year | 2001>2010 |

| Variant | 1.9 JTD (80/115) |

| Rotor Diameter | 284 |

| Rotor Thickness | 22 |

| Min Rotor Thickness | 20.2 |

| Offset (Rotor Height) | 43.5 |

| Centre Bore Diameter | 58 |

| Rotor Configuration | Single Piece |

| Weight | 6.25 |

| Make | Model | Variant | Year |

|---|---|---|---|

| FIAT | Stilo | 1.9 JTD (80/115) | 2001 - 2010 |

This website lists our entire range - it is not linked to our stock system. If you would like to check the availability of any items before ordering please call the office or get in touch via the Contact Us page.

Orders are shipped via USPS or FedEx when shipped from existing US based inventory locations. We aim for same day or next day dispatch, and given this, depending on your exact time of order, and location, we ask that customers allow up to 5 working days for delivery.

If there should be a problem with your order/shipping and it seems likely your order will take longer than 5 days, then we will inform you by email or phone. Deliveries may require a signature so if possible please give a delivery address where the order can be signed for during working hours.

Due to our vast catalog it will often be necessary to ship your special order items from TAROX Italy (via TNT, delivered by FedEx) or from TAROX UK. Items shipped from Italian or UK inventory typically take 5 to 10 working days to be delivered. On occasion, there may be zero inventory of an item at any of our international locations. If this should be the case then we will inform you by email/phone as soon as we find out.

Brake kits and Bespoke rotors are always manufactured to order (MTO). We kindly ask that you allow 3 to 4 weeks for delivery.

All orders shipping from International stock locations are intended to be delivered duty paid, i.e. you should not have to pay any import costs of any kind to either FedEx or CBP. Unfortunately, due to the number of agencies involved, on occasion you may be sent an invoice for customs charges. Please do NOT pay this and request a refund for these charges, we will not be able to refund you, merely issue a future credit note to that value. We must insist that you forward the incorrect paperwork to us, and we will take care of of the invoice ourselves.

Should you have any questions about our shipping and delivery process, please contact us here.